diamond tools store opens the doors to a specialized world where expert craftsmanship meets cutting-edge technology, designed for those who demand the best from their tools. Whether you are a professional contractor, a passionate DIY enthusiast, or an industry specialist, these stores bring together a curated selection of diamond tools backed by quality assurance and authentic brands.

Within a diamond tools store, you’ll find everything from cutting, grinding, drilling, to polishing tools, each meticulously crafted for specific materials and tasks. With trusted brands, robust quality control, and knowledgeable staff, customers can confidently select products suited to construction, fabrication, glasswork, or unique industry needs. These stores don’t just provide tools—they offer guidance, innovation, safety, and dedicated after-sales support, ensuring every purchase is a step towards better results.

Overview of Diamond Tools Stores

Diamond tools stores are specialized retail environments dedicated to supplying high-performance tools that feature industrial-grade diamond components. These stores primarily cater to professionals and enthusiasts in construction, stone fabrication, glasswork, and advanced manufacturing. Customers typically include contractors, fabricators, and anyone requiring precise material processing with durability and efficiency.

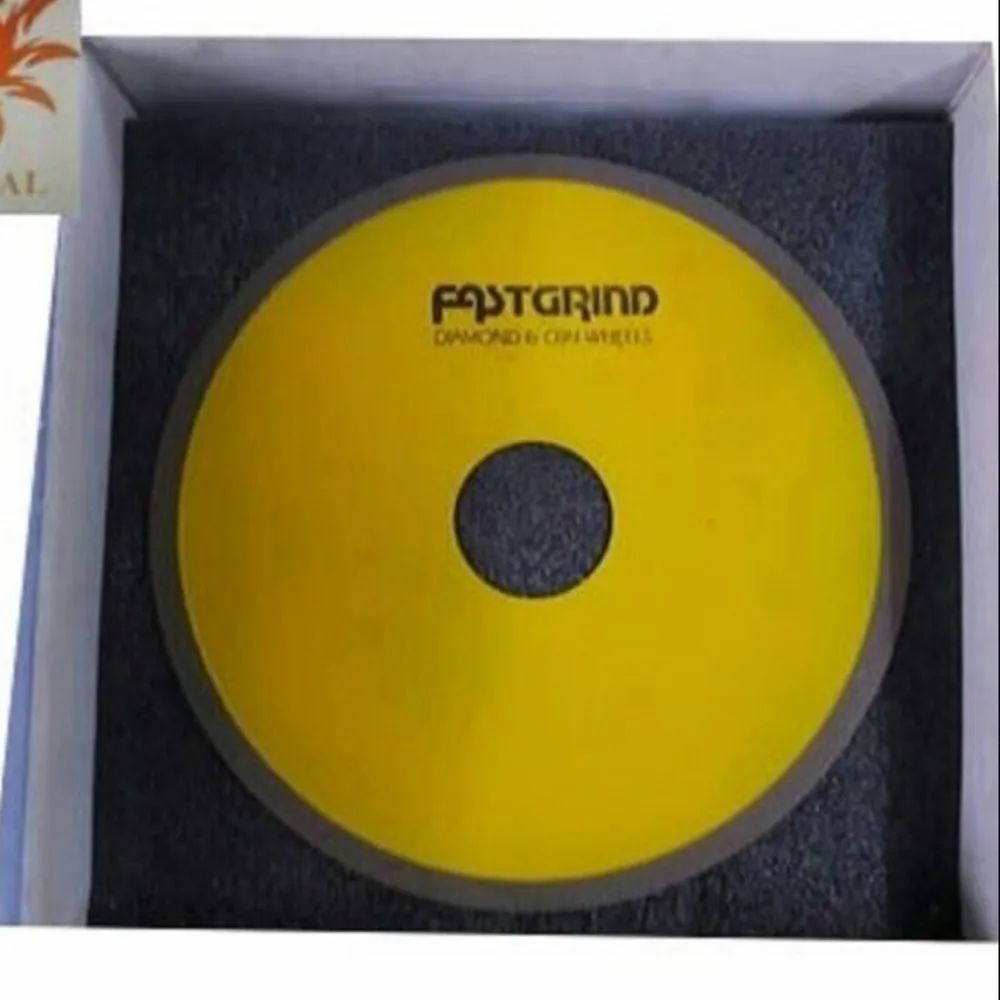

Most diamond tools stores offer a curated selection of tools to support a wide variety of applications. The typical categories include cutting blades, grinding wheels, drilling bits, and polishing pads, each designed for use with specific materials such as concrete, ceramics, stone, or glass. Accessories and tool maintenance products are also commonly found.

The Importance of Quality Control and Authenticity

Quality control is critical in diamond tool retail, as tool performance and safety heavily depend on the integrity of diamond grits and bonding methods. Reputable stores ensure their products meet rigorous standards, often providing certification or detailed product specs. Authenticity also matters—customers should expect transparent sourcing, trustworthy brand affiliations, and clear documentation to avoid counterfeit or substandard tools.

Types of Diamond Tools Available

Diamond tools come in various forms to meet the demands of precision machining and material shaping. Here is a practical summary of the main types, their uses, materials involved, and notable brands in the market:

| Tool Type | Typical Use | Material | Notable Brands |

|---|---|---|---|

| Diamond Cutting Blades | Segmented cutting of concrete, tile, and stone | Steel core with synthetic diamond segments | Husqvarna, Bosch, Norton |

| Diamond Grinding Wheels | Smoothing and shaping hard surfaces | Resin or metal bond with embedded diamonds | DEWALT, Makita, Hilti |

| Diamond Drill Bits | Creating holes in glass, tile, or stone | Nickel-plated or sintered diamond tips | Bosch, Rubi, Milwaukee |

| Diamond Polishing Pads | Finishing and polishing granite, marble, or glass | Flexible resin with diamond grit | 3M, Alpha Tools, Stadea |

Differences Between Cutting, Grinding, Drilling, and Polishing Tools, Diamond tools store

While all diamond tools leverage the hardness and abrasive qualities of diamond, they are engineered for distinct mechanical actions. Cutting blades focus on segmenting or slicing, using sharp, robust segments to penetrate dense materials. Grinding wheels are made for abrasion, efficiently reducing surface roughness or shaping edges. Drill bits employ a concentrated edge or tip to bore clean holes. Polishing pads, with their finer grits, deliver smooth, glossy finishes.

Each type has its pros and cons: for example, cutting blades excel at fast, deep cuts but may leave rougher edges, whereas polishing pads offer superior surface finish but require more time and care. Selecting the right tool involves balancing speed, precision, and desired end quality.

Key Features to Consider When Shopping

Before purchasing diamond tools, customers should evaluate several critical features to ensure optimal performance and value. Understanding these characteristics is key to achieving professional results and extending tool life.

Essential Features in Diamond Tools

Below is a list of important features to assess, each contributing to the suitability of a tool for specific jobs:

- Grit Size – Determines the coarseness or fineness of material removal and finish.

- Bonding Material – Affects how diamonds are retained and released; metal, resin, or hybrid bonds are common.

- Tool Lifespan – Indicates durability based on construction quality and material compatibility.

- Compatibility – Ensures the tool matches with the target material and machinery (angle grinders, saws, drills, etc.).

These features directly impact how effectively a tool performs. For instance, a finer grit size produces smoother surfaces but may reduce cutting speed, while a harder bond is ideal for soft materials to prevent premature diamond loss, but may wear out quickly on harder substrates. Accurate matching of features to the application ensures efficiency and professional-grade results.

Applications and Industries Served

Diamond tools are integral to numerous industries that demand precision, durability, and high performance. Their adoption enhances productivity and quality in fields as diverse as construction, automotive, glasswork, and semiconductor manufacturing.

Industry-Specific Uses of Diamond Tools

The table below shows how different industries employ diamond tools for specialized applications:

| Industry | Application | Tool Used | Desired Result |

|---|---|---|---|

| Construction | Cutting reinforced concrete slabs | Diamond Saw Blade | Accurate, clean, and fast cuts |

| Stone Fabrication | Polishing granite countertops | Diamond Polishing Pads | Glossy, scratch-free finish |

| Glasswork | Drilling holes for fixtures | Diamond Drill Bit | Precise, chip-free holes |

| Automotive | Grinding brake rotors | Diamond Grinding Wheel | Evenly resurfaced brake components |

Each industry has unique requirements regarding tool selection. For instance, construction often prioritizes cutting speed and tool robustness, while stone fabrication demands high polish quality and minimal chipping. Glasswork emphasizes precision and minimal material fracturing. This means stores must offer a broad range of tool types and specifications to address the diverse needs of their customers.

Selecting the Right Diamond Tool for Your Needs: Diamond Tools Store

Matching the right diamond tool to a specific task involves understanding the material, job complexity, and desired outcome. By following a systematic approach, users can maximize efficiency and avoid costly mistakes.

Steps to Find the Suitable Tool

The process starts with material identification, then moves to job assessment, and finally tool selection based on compatibility and performance characteristics.

For example, if a contractor needs to cut thick granite slabs for a kitchen project, they first determine the slab’s hardness and thickness. Next, they select a segmented diamond blade with a medium grit and strong metal bond, ensuring it is rated for both granite and the saw model in use. They also consider blade diameter and cooling requirements to prevent overheating and premature wear during high-volume cutting.

Evaluating tool suitability involves checking the hardness of the target material, expected workload, and the precision required. For very hard or abrasive materials, a tool with a tougher bond and higher diamond concentration is preferable, while softer or brittle materials may benefit from a softer bond and finer grit to reduce the risk of chipping or cracking. Considering these factors leads to safer, more reliable, and cost-effective tool use.

Maintenance and Care for Diamond Tools

Proper maintenance is essential for extending the lifespan and preserving the effectiveness of diamond tools. Neglecting care routines can lead to premature wear, reduced performance, or even tool failure.

Step-by-Step Maintenance Guide

Regular cleaning, safe storage, and timely inspection ensure optimal tool condition. Here is a recommended procedure:

- Clean the tool after each use to remove dust, slurry, and debris with water and a gentle brush where appropriate.

- Dry thoroughly to prevent rust or corrosion, especially if the tool has a steel core.

- Inspect for visible wear, cracks, or damaged segments before and after use.

- Store in a dry, organized place, away from direct sunlight or humidity to avoid degradation.

- Follow manufacturer’s guidelines for periodic dressing or sharpening to maintain effectiveness.

Improper maintenance can result in clogged segments, overheating, loss of diamond particles, or dangerous breakage. By adhering to proper care routines, users ensure safety, consistent performance, and a longer usable life for their diamond tools.

Innovations and Trends in Diamond Tools Retail

The diamond tool industry has seen significant advancements in both manufacturing and retail practices. These innovations aim to improve efficiency, sustainability, and customer experience.

Recent Developments in Diamond Tool Technology

Modern diamond tools benefit from enhanced diamond bonding methods, such as vacuum brazing and laser welding, which provide superior durability and cutting accuracy. Eco-friendly production processes are gaining momentum, with manufacturers adopting recycled steel cores and minimizing harmful chemicals in resin bonds.

Digital customization is another trend, allowing customers to specify tool dimensions, grit sizes, and bonding types online for made-to-order solutions. Online storefronts now offer interactive features such as live product demos, virtual consultations, and AI-driven tool selection guides. These advancements help users make informed choices, reduce waste, and achieve better results with less effort.

Shopping Experience in Physical vs. Online Stores

Customers can purchase diamond tools from both brick-and-mortar stores and online retailers, each offering distinct advantages and trade-offs.

Comparison of Store Types and Customer Support

The following table summarizes the typical differences between shopping environments:

| Store Type | Product Range | Customer Support | Return Policy |

|---|---|---|---|

| Physical Store | Specialized, hands-on selection | In-person advice, tool demos | Immediate, often with on-site exchanges |

| Online Store | Broader inventory, more brands | Live chat, email, remote video support | Mail returns, longer processing time |

Physical stores excel in personal interaction and real-time problem-solving, ideal for customers who prefer to handle and compare tools directly. Online stores provide convenience, greater selection, and advanced self-service resources, often with detailed guides and reviews. Both environments are improving their support offerings to meet rising customer expectations in a competitive market.

Safety Considerations When Using Diamond Tools

Effective use of diamond tools requires strict adherence to safety protocols, as these tools operate at high speeds and deal with tough materials.

Safety Checklist for Diamond Tool Users

To minimize risks, customers should follow this safety checklist:

- Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, dust masks, and ear protection.

- Check tool and machine compatibility before use.

- Inspect tools for damage, cracks, or excessive wear before each operation.

- Follow manufacturer’s operating instructions, including speed ratings and usage limits.

- Use proper coolant or water if required, especially when cutting or grinding hard materials.

- Maintain a clean work area to prevent slips and accidental tool contact.

- Never force the tool; let the diamonds do the cutting or grinding work.

User education and readily available safety information, often provided by reputable stores, play a significant role in accident prevention. Proper training and support resources empower users to operate safely and efficiently, protecting both themselves and their equipment.

Customer Support and After-Sales Service

A reputable diamond tools store stands out by offering comprehensive after-sales services, ensuring customer satisfaction and loyalty long after the purchase.

After-Sales Services Provided by Diamond Tools Stores

Typical support options include product warranties covering defects, access to technical support for troubleshooting, and repair or replacement services for eligible tools. Many stores also provide online resources such as instructional videos, maintenance guides, and live chat for quick assistance.

Warranty options can range from limited coverage to extended plans, depending on the manufacturer and retailer. For customers, leveraging these resources is best done by registering products upon purchase, retaining receipts, and familiarizing themselves with support channels. Proactive communication with the store can expedite solutions if any issues arise, ensuring continued performance and peace of mind with every diamond tool investment.

Concluding Remarks

In summary, a diamond tools store is more than just a shopping destination—it’s a hub of expertise, quality, and customer care for anyone seeking precision solutions. With a wide range of tools, innovative trends, and attentive support, finding the right diamond tool has never been easier or more reliable. Step into a world where performance and service come together seamlessly for every project.